Processing

To ensure you get the world’s finest quality rice, only TIGER RICE has developed unique & special 8-steps Octa-Q Process. This Process starts with sourcing & selecting from authentic rice origins. It all begins in the lush green fertile fields of Punjab, Pakistan that are watered by snow fed rivers originating from Himalayas.

Growing and Harvesting

Rice is a Kharif (Autumn) crop, which means that the planting, cultivation and harvesting is done in monsoon season of the Asian subcontinent. June – July is the season of plantation of rice and harvesting season starts in September and goes till November.Different varieties of rice takes different amount of time to reap hence have different harvesting time.

Paddy Selection

If low quality grain is used then no experience or machinery can turn that into high quality output. Therefore, after thorough examination only the finest paddy is selected. Absolutely no compromise is made in paddy selection process.

Paddy Cleaning

As paddy arrives at TIGER RICE, all impurities such as dirt, stones, etc are removed. If there are immature grains found then they are also discarded. As much care as possible is used during this process. Modern technology is used for efficient drying of rice paddy. All moisture from the paddy is dried using state of the art dryers.

Milling and Warehousing

In the milling section of the process, the husk of the dried paddy rice is then removed. The whole grain obtained in the process is of brown color and it is the first time when the paddy turns into rice. The rice obtained is of brown texture due to bran layers on it. Since ageing is what makes rice perfect, TIGER RICE pioneered the use of modern moisture and temperature controlled high-tech storage systems where rice is carefully aged for atleast 1 year to bring out the full natural aroma, taste and goodness.

Rice To Rice

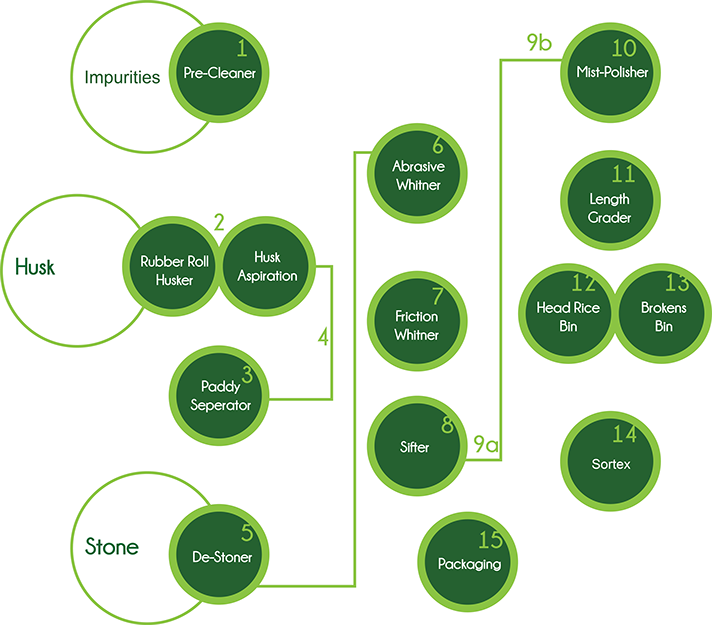

Pre-Cleaning

Once again a quality check is done on the rice to make sure that the rice that is going through this process is clean of any sort of impurity (stones, threads etc).

Polishing

To give the rice fine and silky texture, the rice is passed through polisher. For this process two polishers are used according to the requirement.

Grading

Length Grading and thickness grading is then performed to check the thickness and length of the grain. Uniformity in size is achieved by separating broken and shriveled grains.

Color Sorting

Color sorting is computer-controlled process where CCD technology is used for high-resolution-optical inspection of each and every grain. Eventually to ensure high quality of the product discolored and damage grains are separated using state of the art high tech color sorting unit.

Packaging

TIGER RICE has installed modern computerized bagging scales to ensure high degree of accuracy in weighing. Packaging process is carefully designed and performed to increase shelf life of products as well as easy handling till the point of consumption. TIGER RICE goes extra miles to present its products in beautiful, eye-catching and striking designs. Several types of packaging material (i.e. Jute, Cotton, Polypropylene, Polythene, P.E, are used as per customer demands.

Rice Processing Flow Chart

RICE ANATOMY

Rice Bran

Amazingly, rice bran was once considered a trash product and was only used for livestock feed. Fortunately, we now know better! Rice bran is astoundingly healthy for you: Every ounce of rice bran delivers a full 6 grams of fiber —one quarter of the recommended daily allowance — and is a good source of iron, vitamin B6, potassium, thiamine, niacin, manganese, and phosphorus.

Hull

The hull of the rice grain is not edible by humans and is removed during processing. Because of its high silica content has tremendous potential as an industrial product.

White Rice

White rice gets an unnecessary bad rap! White rice is full of nutrition, with one cup delivering 12 percent of RDA for niacin, 23% for folate, 17% for thiamin, and 37% for manganese!